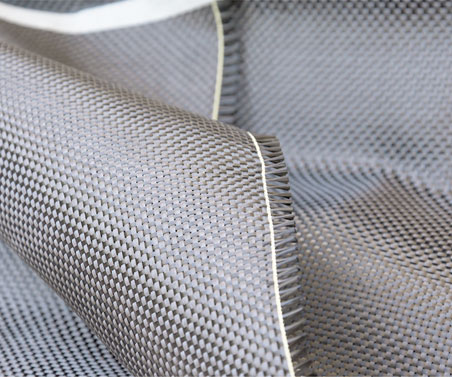

SMC Roving

Multi-end roving isn’t just any fiber; it’s a game-changer for large-surface Sheet Molding Compound (SMC) components. Think of it as the Swiss Army Knife of the composite world, offering a unique blend of features that cater to efficiency, strength, and beauty:

Efficient Processing:

- Faster cycle times: No need for twisting, leading to quicker fabrication and higher production volumes.

- Reduced waste: Uniform fiber distribution minimizes scrap and optimizes material usage.

- Lower costs: Streamlined processing translates to cost savings per component.

High Mechanical Properties:

- Superior strength and stiffness: Excellent load-bearing capacity for demanding applications.

- Dimensional stability: Maintains shape under pressure and temperature variations.

- Improved impact resistance: Withstands external forces without cracking or breaking.

Aesthetic Properties:

- Smooth surfaces: Achieves a clean, even finish for visually appealing parts.

- Paintability: Easily accepts a variety of paints and coatings for customization.

- Design flexibility: Can be molded into complex shapes, unlocking creative possibilities.

Ideal Applications:

- Automotive panels: Doors, roofs, hoods, and other large components.

- Building and construction: Roofing sheets, wall panels, and architectural elements.

- Transportation: Bus and truck panels, boat hulls, and aircraft interiors.

- Household appliances: Washing machines, dryers, and refrigerators.

The bottom line: Multi-end roving isn’t just a material; it’s a strategic choice for optimizing production, maximizing performance, and achieving desired aesthetics in large-scale SMC components.

I hope this expanded and rewritten version provides a more comprehensive and engaging description of multi-end roving for SMC applications.

For more information, please contact us by filling out below form

Get a cost estimate

Please submit a detailed outline of your business requirement so that our team of experts could get in touch with you with a customised product/service cost estimate within the next 48 hours.

Featured Products

Composites

FRP Services & Company offices in 18+ cities in 12+ countries

Global Network

HEADQUARTERS

- FRP SERVICES & COMPANY FRP bldg., 1-15-9 Awaza, Nishi-ku, Osaka Japan 550-0011

- +81 (6) 6535-1933

- [email protected]

REGIONAL OFFICE

- FRP SERVICES & COMPANY KDX Nihonbashi Edo-dori Bldg, 8F 3-9-4, Nihonbashi-honcho, Chuo-ku, Tokyo Japan 103-0023

- +81 (0) 3 5643 8061

- [email protected]

INDIA

- FRP SERVICES & CO INDIA PVT LTD, F 104, Ascot Centre, Sahar Airport Road, Andheri - East, Mumbai India 400099

- +91-22-28351401

- [email protected]

SRI LANKA

PAKISTAN

- FRP SERVICES & COMPANY (P.L.O) Business Arcade, 3rd Floor, Suit# 309, Shahrah-e-Faisal, Karachi Pakistan 75400

- +92 (21) 3432 7632

- [email protected]

PHILIPPINES

- TY COMPOSITE INTERNATIONAL CORPORATION National Highway Teco Industrial Park, Brgy. Bundagul, Mabalacat City, Pampanga 2010 Philippines

- +63-45-403-9914

- [email protected]

VIETNAM

HANOI REPRESENTATIVE OFFICE

- FRP SERVICES & COMPANY Room 402,04th floor, Vinahud Building, Trung Yen 9 road, Cau Giay District, Hanoi, Vietnam.

- +84 (24) 3728 2357

- [email protected]

VIETNAM

HO CHI MINH OFFICE

- FRP SERVICES & COMPANY CSI Business Centre, Room 202, 2th Floor, Ben Thanh Building 70 Ly Tu Trong Str, Ben Thanh Ward, District 1,Ho Chi Minh City, Vietnam

- +84 (28) 3827 2199

- [email protected]

TAIWAN

- TAIPEI REPRESENTATIVE OFFICE 7F-9, No. 207, Tung-Hwa North Road, Taipei, Taiwan

- +886 (2) 2713 3111

- [email protected]

SINGAPORE

- FRP SERVICES (ASIA) PTE LTD. 24 Raffles Place #17-04A Clifford Centre Singapore 048621

- +65 6270 5001

- [email protected]

CHINA

- FRP SERVICES & CO. SHANGHAI OFFICE Shanghai International Trade Center, 25 #2508, 2201 Yan An Road (West), Shanghai 200336, China

- +86-21-6209-5907

- [email protected]

FRANCE

- FRP SERVICES EUROPE SARL Square de l’Arbois Bât. B3 565 Rue René Descartes, 13857 Aix-en-Provence Cédex3, France

- +33 (0) 4 4297 5910

- [email protected]

UAE - DUBAI

- FRP SERVICES & COMPANY MIDDLE EAST (BRANCH) 4WA, 628, Dubai Airport Free Zone, Dubai, UAE

- +971 (4) 204 5050

- [email protected]

NORTH AMERICA - USA

REGIONAL HEADQUARTERS

- FRP SERVICES & CO. (AMERICA) INC. 535 Fifth Avenue, Suite 1008, New York, NY 10017, U.S.A

- +1 (212) 695 8000

- +1 (212) 695 3100

- [email protected]

NORTH AMERICA – CANADA

REGIONAL BRANCH OFFICE

SOUTH AMERICA

BRAZIL REP OFFICE

- FRP SERVICES & CO. (AMERICA) INC. Avenida Pompeia, 634 - Suite 501, Vila Pompeia, São Paulo, CEP 05022-000 Brazil

- +55 (11) 3589 5749

- +55 (11) 3589 5709

- [email protected]

Meet Us

Contact

Composites Division

Composites Division

Address: FRP SERVICES EUROPE SARL

Square de l’Arbois Bât.

B3 565 Rue René Descartes,

13857 Aix-en-Provence Cédex3,

France

Telephone: +33 (0)4 42 97 59 10

Fax: +33(0)442975920

Website: http://frpserv.com/eu-en

Email:

[email protected]