Basalt Fiber

Product Characteristics

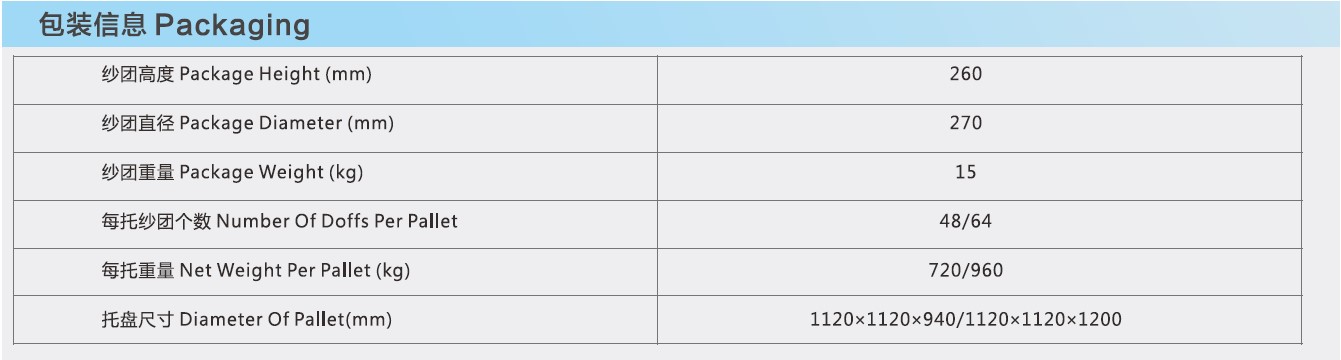

Packaging

BFR-711

Fiber specifications

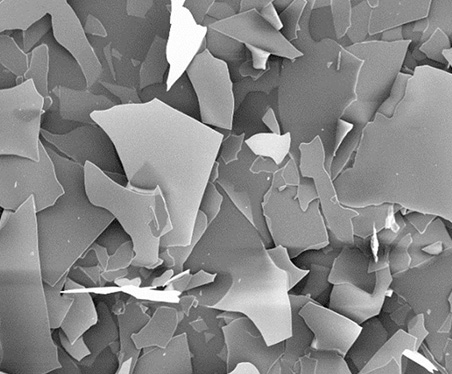

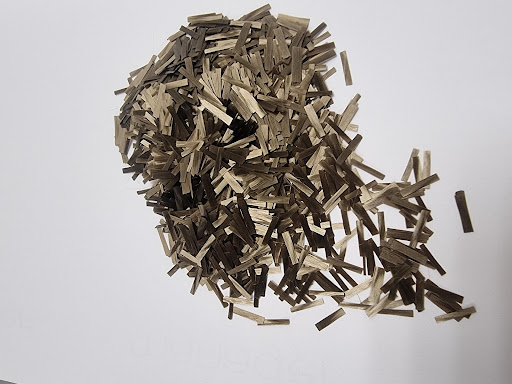

BFR-711 is a basalt chopped strand.

This product is coated with a silane-based sizing agent which is designed for compatibility with UP and acrylic resins.

BFR-711 has excellent resin wetting and fiber dispersion.

It is designed for application in panels. Basalt fiber can prolong its life, can improve its performance and can reduce the cost of the project, so it has a strong commercial value. This paper focuses on the short shear basalt fiber reinforced cement mix.

The product is added to the cement mix to improve the mechanical properties and service performance of the surface.

The addition of basalt fiber in the cement mix can improve fracture resistance and anti-ageing crack resistance to significantly extend the service life of the concrete artefact.

Product characteristics

- Excellent mechanical property.

- Good static control and cuttability.

- Fast external wetting.

- Exceptional dispersion.

- Good stability at high temperatures.

- Good crack resistance at low temperatures.

Technical data sheet

| Unit of measurement | Technical indicators | Test method | |

|---|---|---|---|

| Tensile strength of immersed yarns | MPa | 17 my = 2400 13 my = 2500 |

GB / T 20310 |

| Fracture resistance | N/Tex | 17 my: ≥ 0,4 13 my: ≥ 0,5 |

GB / T 7690.3 |

| Elongation at break | % | ≤ 3.1 | GB / T 7690.3 |

| Water content | % | ≤ 0.1 | GB / T 9914.1 |

| Presence of fuel content | % | ≤ 0.5 | GB / T 9914.2 |

| Density | g/cm3 | 2.6 - 2.7 | ISO 1183-1 |

| Oil absorption | % | ≥50 | - |

| Moisture content | % | ≤0.2 | - |

| Flammability | - | None | - |

| Heat resistance | % | ≥85 | - |

| Elasticity | GPa | ≥80 |

Functional indicators:

| Unit of measurement | Technical indicators | |

|---|---|---|

| Thermal conductivity | W / (m · K) | 0.030 - 0.038 |

| Volume resistance | Ω · m | 1 * 10 ^ 12 |

| Chemical composition: total iron oxides |

% | ≥ 7.0 |

Data parameters:

| Type of sizing | Silane |

| Filament (my) | 13 / 17 |

Technical parameters:

| Linear density (%) |

Moisture content (%) |

Size content (%) | Rigidity (mm) |

|---|---|---|---|

| ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| ± 5 | ≤ 0.10 | 0.6 ± 0.15 | ≥ 105 |

Packaging

BFR-711 is available packed in 20 kg plastic bags in oktabin or pallets, or other

packaging on request.

Basalt fiber is a brittle inorganic material, bending and contact with rough

surfaces should be avoided and unnecessary friction reduced.

Storage:

BFR-711 should be stored in a dry, cool, moisture-proof area and should remain

in its original packaging until used.

Validity:

BFR-711 remains valid for up to 12 months from the date of leaving the factory.

BFR-202

BFR-202 (13 / 17 my)

Available lengths: 3mm / 6mm / 12mm

Fiber specifications

BFR-202 are basalt chopped strand.

This product is coated with a silane-based sizing agent

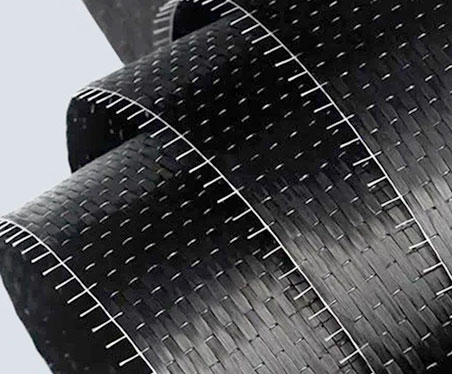

It is designed for use in reinforcing asphalt and concrete mixes, both in new construction and revitalised projects. Basalt fibre can extend the life of the road and its surface, can improve its performance and can reduce the cost of the project, so it has a strong commercial value. This paper focuses on the analysis of short cut basalt fibre and its properties.

This product is added to the asphalt and/or cement mix to improve the mechanical properties and service performance of the surface. The addition of basalt fibre to the mix can improve pavement fracture resistance and anti-ageing crack resistance, thus significantly extending the service life of the pavement.

Basalt fibre is the best choice of reinforcement fibres for pavements, as they are quite unique and exclusive.

Product characteristics

- Excellent mechanical property.

- Good static control and cuttability.

- Fast external wetting.

- Exceptional dispersion.

- Good stability at high temperatures.

- Good crack resistance at low temperatures.

Technical data sheet

| Unit of measurement | Technical indicators | Test method | |

|---|---|---|---|

| Tensile strength of immersed yarns | MPa | 17 my = 2400 13 my = 2500 |

GB / T 20310 |

| Fracture resistance | N/Tex | 17 my: ≥ 0,4 13 my: ≥ 0,5 |

GB / T 7690.3 |

| Elongation at break | % | ≤ 3.1 | GB / T 7690.3 |

| Water content | % | ≤ 0.1 | GB / T 9914.1 |

| Presence of fuel content | % | ≤ 0.5 | GB / T 9914.2 |

| Density | g/cm3 | 2.6 - 2.7 | ISO 1183-1 |

| Oil absorption | % | ≥50 | - |

| Moisture content | % | ≤0.2 | - |

| Flammability | - | Niente | - |

| Heat resistance | % | ≥85 | - |

| Elasticity | GPa | ≥80 |

Functional indicators:

| Unit of measurement | Technical indicators | |

|---|---|---|

| Thermal conductivity | W / (m · K) | 0.030 - 0.038 |

| Volume resistance | Ω · m | 1 * 10 ^ 12 |

| Chemical composition: total iron oxides | % | ≥ 7.0 |

Data parameters:

| Type of sizing | Silane |

| Filament (my) | 13 o 17 |

Comparison of different fibres applied in asphalt pavements:

| Name | Advantages | Disadvantages |

|---|---|---|

| Carbon fibre | improves resistance to high temperature, increases technological properties and improves crack resistance at low temperature. | It is expensive and difficult to disperse. |

| E-Glass fibre | Improve the property, strength and stability of asphalt. | Fragile, poor resistance to usury. |

| Synthetic and lignin fibres | Improve high temperature performance, low temperature crack resistance, water stability and fatigue resistance of the asphalt mix. | When the fibre content exceeds a certain value, the stability first increases and then decreases. |

| Basalt fibre | After the addition of the fibre to the asphalt mortar, the concentrated interface stress is released, the stress relaxation capacity is improved, the fatigue damage of the mix is significantly reduced, and the shear strength and erosion resistance modulus are | When the fibre content exceeds a certain value, the stability first increases and then decreases. |

Packaging

BFR-202 is available packed in 20 kg plastic bags in oktabin or pallets, or other packaging on request.

Basalt fiber is a brittle inorganic material, bending and contact with rough surfaces should be avoided and unnecessary friction reduced.

Storage:

BFR-202 should be stored in a dry, cool, moisture-proof area and should remain in its original packaging until used.

Validity:

BFR-22 remains valid for up to 12 months from the date of leaving the factory.

For more information, please contact us by filling out below form

Get a cost estimate

Please submit a detailed outline of your business requirement so that our team of experts could get in touch with you with a customised product/service cost estimate within the next 48 hours.

Featured Products

Composites

FRP Services & Company offices in 18+ cities in 12+ countries

Global Network

HEADQUARTERS

- FRP SERVICES & COMPANY FRP bldg., 1-15-9 Awaza, Nishi-ku, Osaka Japan 550-0011

- +81 (6) 6535-1933

- [email protected]

REGIONAL OFFICE

- FRP SERVICES & COMPANY KDX Nihonbashi Edo-dori Bldg, 8F 3-9-4, Nihonbashi-honcho, Chuo-ku, Tokyo Japan 103-0023

- +81 (0) 3 5643 8061

- [email protected]

INDIA

- FRP SERVICES & CO INDIA PVT LTD, F 104, Ascot Centre, Sahar Airport Road, Andheri - East, Mumbai India 400099

- +91-22-28351401

- [email protected]

SRI LANKA

PAKISTAN

- FRP SERVICES & COMPANY (P.L.O) Business Arcade, 3rd Floor, Suit# 309, Shahrah-e-Faisal, Karachi Pakistan 75400

- +92 (21) 3432 7632

- [email protected]

PHILIPPINES

- TY COMPOSITE INTERNATIONAL CORPORATION National Highway Teco Industrial Park, Brgy. Bundagul, Mabalacat City, Pampanga 2010 Philippines

- +63-45-403-9914

- [email protected]

VIETNAM

HANOI REPRESENTATIVE OFFICE

- FRP SERVICES & COMPANY Room 402,04th floor, Vinahud Building, Trung Yen 9 road, Cau Giay District, Hanoi, Vietnam.

- +84 (24) 3728 2357

- [email protected]

VIETNAM

HO CHI MINH OFFICE

- FRP SERVICES & COMPANY CSI Business Centre, Room 202, 2th Floor, Ben Thanh Building 70 Ly Tu Trong Str, Ben Thanh Ward, District 1,Ho Chi Minh City, Vietnam

- +84 (28) 3827 2199

- [email protected]

TAIWAN

- TAIPEI REPRESENTATIVE OFFICE 7F-9, No. 207, Tung-Hwa North Road, Taipei, Taiwan

- +886 (2) 2713 3111

- [email protected]

SINGAPORE

- FRP SERVICES (ASIA) PTE LTD. 24 Raffles Place #17-04A Clifford Centre Singapore 048621

- +65 6270 5001

- [email protected]

CHINA

- FRP SERVICES & CO. SHANGHAI OFFICE Shanghai International Trade Center, 25 #2508, 2201 Yan An Road (West), Shanghai 200336, China

- +86-21-6209-5907

- [email protected]

FRANCE

- FRP SERVICES EUROPE SARL Square de l’Arbois Bât. B3 565 Rue René Descartes, 13857 Aix-en-Provence Cédex3, France

- +33 (0) 4 4297 5910

- [email protected]

UAE - DUBAI

- FRP SERVICES & COMPANY MIDDLE EAST (BRANCH) 4WA, 628, Dubai Airport Free Zone, Dubai, UAE

- +971 (4) 204 5050

- [email protected]

NORTH AMERICA - USA

REGIONAL HEADQUARTERS

- FRP SERVICES & CO. (AMERICA) INC. 535 Fifth Avenue, Suite 1008, New York, NY 10017, U.S.A

- +1 (212) 695 8000

- +1 (212) 695 3100

- [email protected]

NORTH AMERICA – CANADA

REGIONAL BRANCH OFFICE

SOUTH AMERICA

BRAZIL REP OFFICE

- FRP SERVICES & CO. (AMERICA) INC. Avenida Pompeia, 634 - Suite 501, Vila Pompeia, São Paulo, CEP 05022-000 Brazil

- +55 (11) 3589 5749

- +55 (11) 3589 5709

- [email protected]

Meet Us

Contact

Composites Division

Composites Division

Address: FRP SERVICES EUROPE SARL

Square de l’Arbois Bât.

B3 565 Rue René Descartes,

13857 Aix-en-Provence Cédex3,

France

Telephone: +33 (0)4 42 97 59 10

Fax: +33(0)442975920

Website: http://frpserv.com/eu-en

Email:

[email protected]